Manufacturing Software Development Services

We use digital twins, artificial intelligence, and autonomous operations to help manufacturers improve performance, increase productivity, and achieve long-term sustainability.

Get Free Consultation

Manufacturers are shifting towards a collaborative, automated, and integrated model to meet the changing customer demand patterns. While beneficial, this creates complexities for the operations team, which must balance growth, profitability, quality, and sustainability objectives.

With 13 years of experience delivering innovative industrial and manufacturing solutions, we help you overcome these challenges with tailored solutions that digitize your existing operations, transform customer experiences, and automate processes for greater speed, responsiveness, efficiency, and intelligence.

Custom Manufacturing Software Development Services We Offer

Product design and development

Accelerate your product development process and bring innovative designs to market faster.

By employing digital twin technology, advanced simulation software, and virtual reality tools, we help you create optimized product designs, conduct virtual testing, and make data-driven decisions throughout the development cycle.

Production modernization

Improve operational efficiency with real-time visibility, control, and optimization of manufacturing processes .

We integrate advanced automation technologies, such as Industrial IoT (IIoT), edge computing, and machine learning algorithms, with your Manufacturing Execution System (MES) to enable predictive maintenance, quality control, and optimized resource allocation.

Logistics and supply chain management

Streamline your logistics processes and improve your supply chain’s efficiency with our intelligent logistics solutions.

Our IoT-enabled smart warehousing systems automate inventory tracking and material handling. We also enable blockchain-based traceability for full visibility and quality control across your logistics network.

Workforce management

Optimize your workforce based on real-time production requirements and worker skills with an AI task allocation system.

We develop AR/VR applications for virtual training and onboarding using Amazon Sumerian, reducing training time and costs. With Amazon Rekognition, we implement computer vision-based safety monitoring to identify potential hazards.

Sustainable manufacturing

Optimize the use of renewable energy sources and reduce energy consumption with our smart energy management systems.

Built using IoT sensors, machine learning algorithms, and predictive analytics, our serverless solutions help you gain actionable insights, simplify your sustainability reporting, and ensure compliance with regulatory requirements.

It Always Start with Conversation

Why Choose Simform for Manufacturing Services

With deep domain expertise and a customer-centric approach, we help you optimize production, supply chain management, and workforce empowerment and make your manufacturing operations industry 4.0-ready. Our tech stack includes modern technologies, including IoT, blockchain, machine learning, digital twins, and AWS tools, for robust and scalable manufacturing solutions.

Manufacturing industry expertise

As an Microsoft Gold Partner with multiple Azure certifications, we helped manufacturing companies of all sizes optimize their operations, improve product quality, and enhance customer satisfaction with the power of cloud.

Seamless integration and scalability

Our manufacturing solutions integrate seamlessly with your existing systems like ERP, WMS IACS, etc. As they are built with flexibility and interoperability, your operations can scale dynamically to meet demands.

Modern tech stack

Our team is proficient in performance monitoring, business intelligence, event processing, industrial IoT, and smart analytics. We create digital solutions that complement your existing IT infrastructure, scale well, and keep your data secure.

Future-proof adaptability

We build modular and customizable systems that can easily accommodate new production lines, facilities, and product variations, ensuring that your software infrastructure evolves alongside your manufacturing operations.

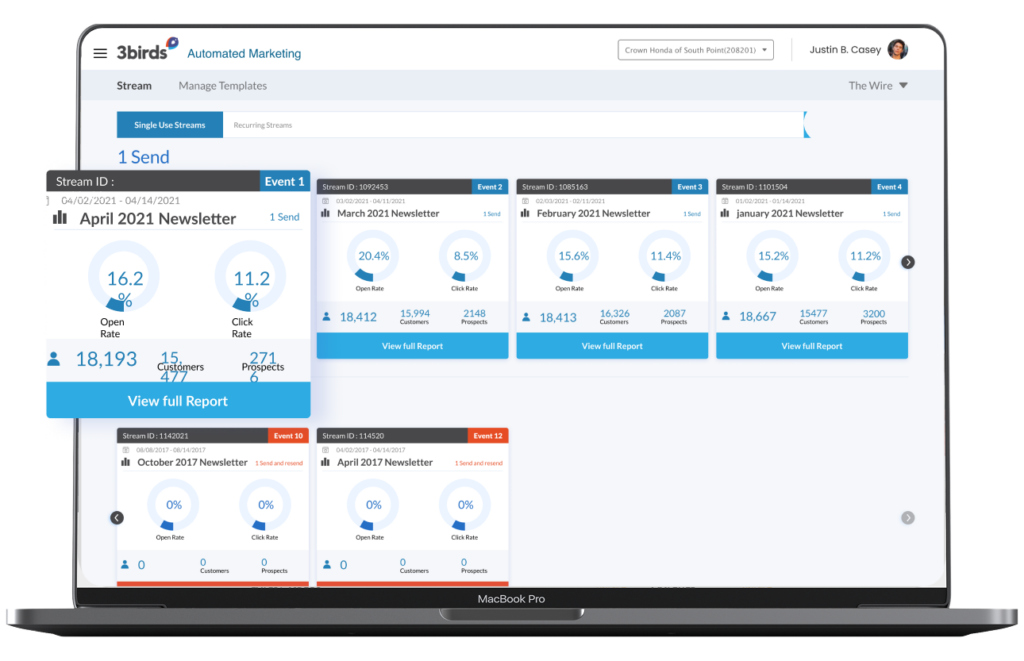

Marketing automation

With our marketing automation solutions, you can streamline your customer engagement processes, leverage data-driven insights, and focus on building strong relationships that drive business growth.

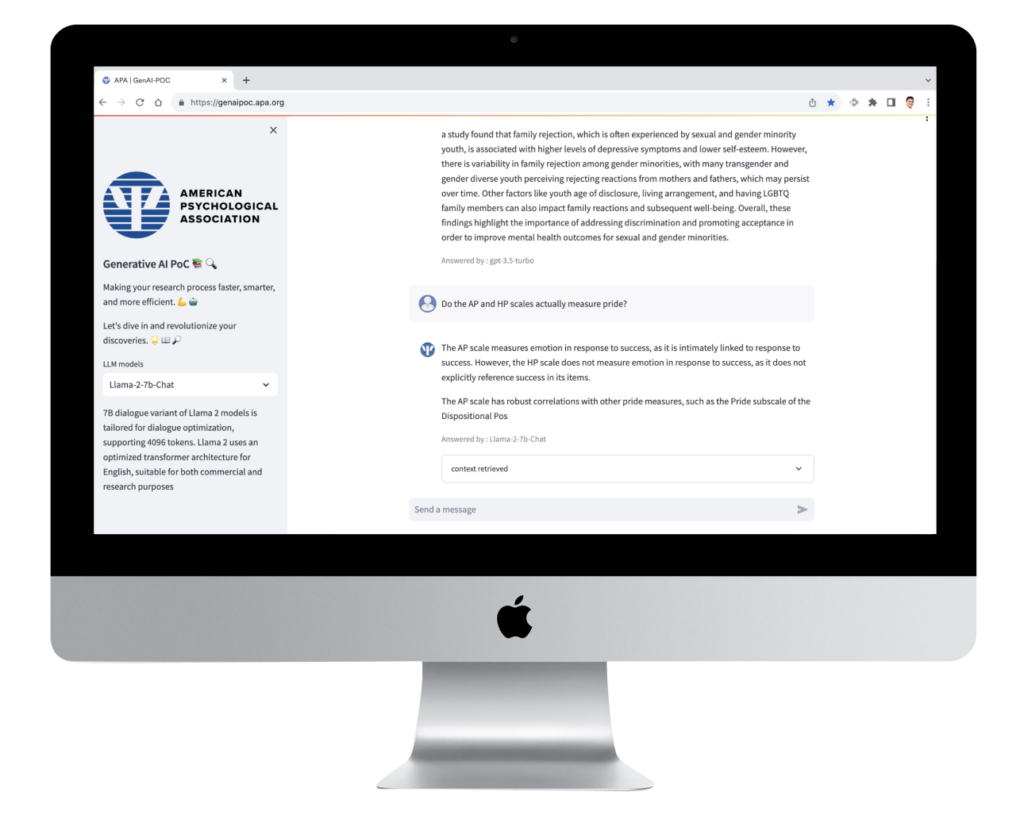

AI Studio advantage

Our special unit’s engineering culture and practices focus on experimentation and innovation. AI Studio has built proprietary libraries and MLOps tools to achieve digital excellence in manufacturing.

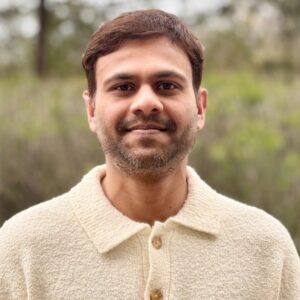

Trusted by the World's Leading Companies

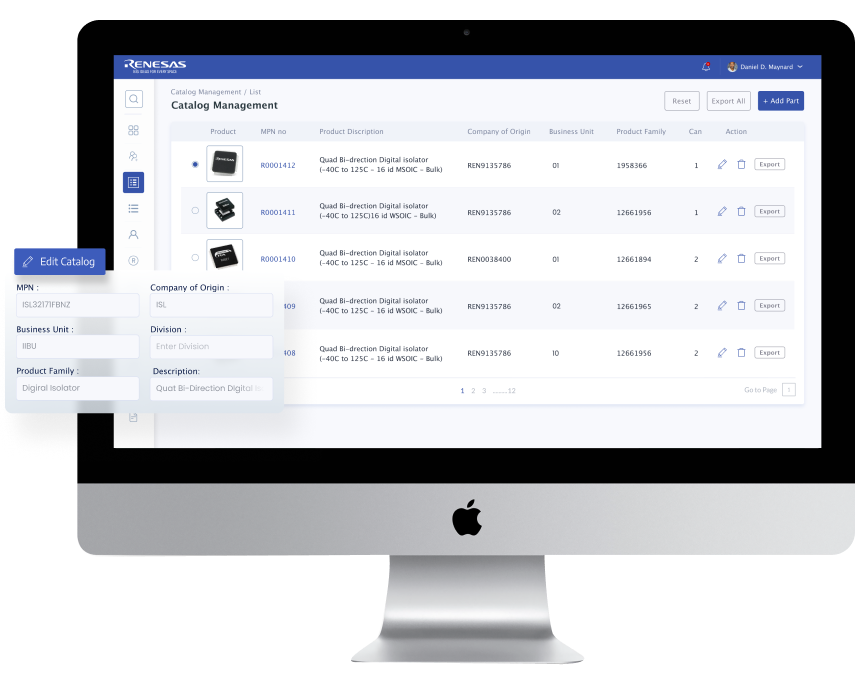

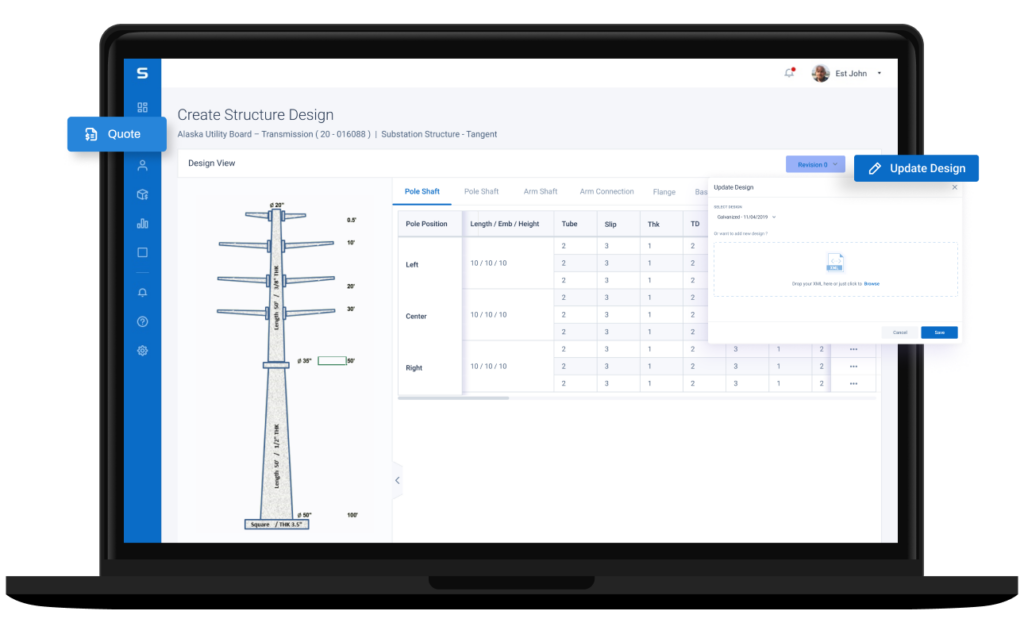

Case Studies

Discover the many ways in which our clients have embraced the benefits of the Simform way of engineering.

From Our Experts

Recognized by Microsoft to Accelerate your Engineering Vision

Let’s talk

Hiren Dhaduk

Hiren Dhaduk

Creating a tech product roadmap and building scalable apps for your organization.